Innovation - i3

Innovation

We explore new product solutions that enhance design, improve durability, reduce weight and offer superior performance.

Every day, our commitment to innovation is helping our customers achieve better results.

When you work with us, you'll discover that we are more than just a parts supplier. Our goal is to solve your unique application challenges and provide the tools you need to outperform expectations.

It may be overcoming a design obstacle or developing a material that changes an industry.

With access to the extensive resources of Cooper Standard, we are finding new ways to improve a wide range of industrial and specialty applications.

Investing in your success

We pursue innovation in every aspect of our business. This mindset guides how we meet the current and future needs of our customers.

Our Approach

- Experienced application and process engineers work with you to improve product design and manufacturing performance.

- Dedicated teams tap into Cooper Standard’s extensive resource network to provide flexible, customized solutions for ISG customers.

- A Global Technology Center in Livonia, Michigan accelerates material science breakthroughs with advanced testing and analytical capabilities.

- Our i3 process invites our employees to imagine, initiate and innovate in order to create new solutions.

Designed for better performance

Through our expertise in material science and market-specific design, we optimize components for our customers' end-use conditions.

We continue to introduce new innovations into the market that can improve performance in a variety of applications.

Innovation Highlights

- MagAlloyTM : A next generation metal coating process that improves longevity of tubing applications.

- FortrexTM : A revolutionary material platform created by Cooper Standard for a variety of sealing applications.

- ArmorHoseTM : A thin layer of abrasive resistant material that replaces the need for abrasive sleeves on hoses.

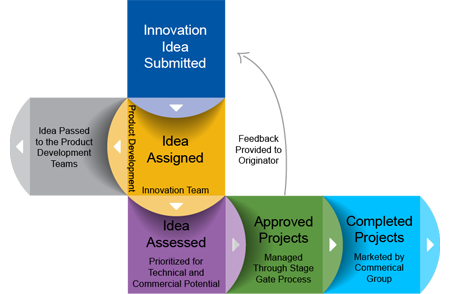

The i3 process

Originally developed to meet the stringent demands of the automotive industry, our i3 process creates a culture in which employees imagine, initiate and innovate to bring new solutions to our customers.

Approximately 30 of the most promising ideas are presented each quarter to be evaluated by Cooper Standard’s Global Technology Council, which includes top R&D executives.

i3 in action

- Imagine an idea that pertains to products, processes and materials related to Cooper Standard’s current core product streams in sealing, fluid transfer and fuel and brake delivery systems.

- Initiate the innovation process by submitting a simple online form, which will be evaluated by the Global Technology Council.

- Innovate as approved projects will enter the innovation or product development stage-gate process until project completion.