There are simply too many variables to say one material will always outperform the other. The decision will be unique to the specific conditions of each application. For instance, it is possible that TPV could effectively replace an EPDM seal while offering lower weight or improved aesthetics. On the other hand, EPDM may be the more cost-effective choice.

The important thing is to not limit yourself to just rubber or plastic options based on the capabilities of a manufacturer. Cooper Standard engineers have experience with both types of materials and can help you make an informed decision.

Joining plastic and rubber

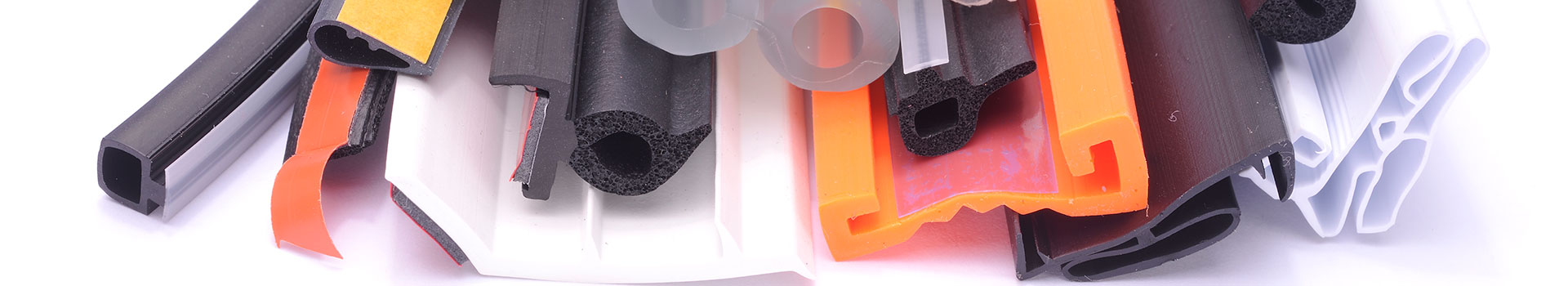

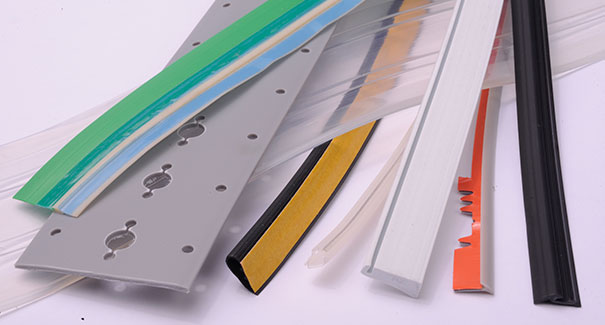

Often, an application calls for a component that has both rigid and flexible features.

Often, an application calls for a component that has both rigid and flexible features.

For instance, a dual-durometer seal may have a rigid portion that is inserted into a channel and a flexible bulb that achieves dynamic sealing properties. Rubber and plastic do not have the compatibility to be co-extruded, so the most common solution is to combine either rigid and flexible plastic or sponge and dense rubber.

Another option is to combine plastic and rubber. Cooper Standard's iDea® Seal products feature a sponge or dense EPDM bulb chemically bonded to a plastic base. These products can easily slide into a channel and will not stretch. Plastic and rubber may also be joined through a mechanical connection. Many times, this involves attaching a plastic extrusion to a rubber component using fasteners such as plastic rivets.

A rubber component also can be designed with a dense base that fits into a channel on a plastic extrusion, effectively creating a single part. To learn more about if rubber or plastic is the right fit for your next project, contact a Cooper Standard engineer.

While there are significant differences between plastic and rubber, these materials can share many performance properties.

While there are significant differences between plastic and rubber, these materials can share many performance properties.

When to use plastic

When to use plastic  Often, an application calls for a component that has both rigid and flexible features.

Often, an application calls for a component that has both rigid and flexible features.