Robotic Cutting Cells For Intricate Parts

At Cooper Standard ISG, we have been making radiator baffles for several commercial vehicle manufacturers and their suppliers for many years. Baffles are a vital under-hood component that directs air to the radiator to provide optimum cooling. Commercial vehicle manufacturers tend to have a lot of different models and configurations of baffles rolling off their assembly lines.

Unlike other extrusion manufacturers, producing relatively small runs of different thermoplastic components is our specialty at Spring Lake. As a result, we’ve been a go-to partner for many commercial vehicle producers, using our extrusion expertise to produce high quality parts.

Meeting the Challenge of a Design Change

We were originally making tens of thousands of baffles using a metal punch or cutting die, which was ideal for the cost and shape of the baffle, as they were normally flat.

One of the challenges we encountered was a design change requested by one of our customers. The redesigned baffles became more complex with angles and required multiple durometer thermoplastics, including a rigid part for mounting and a flexible part for directing airflow. While this design change promised improved performance, it posed cost and practicality challenges for production. To overcome this, we had to rethink our approach.

Introducing the Robot

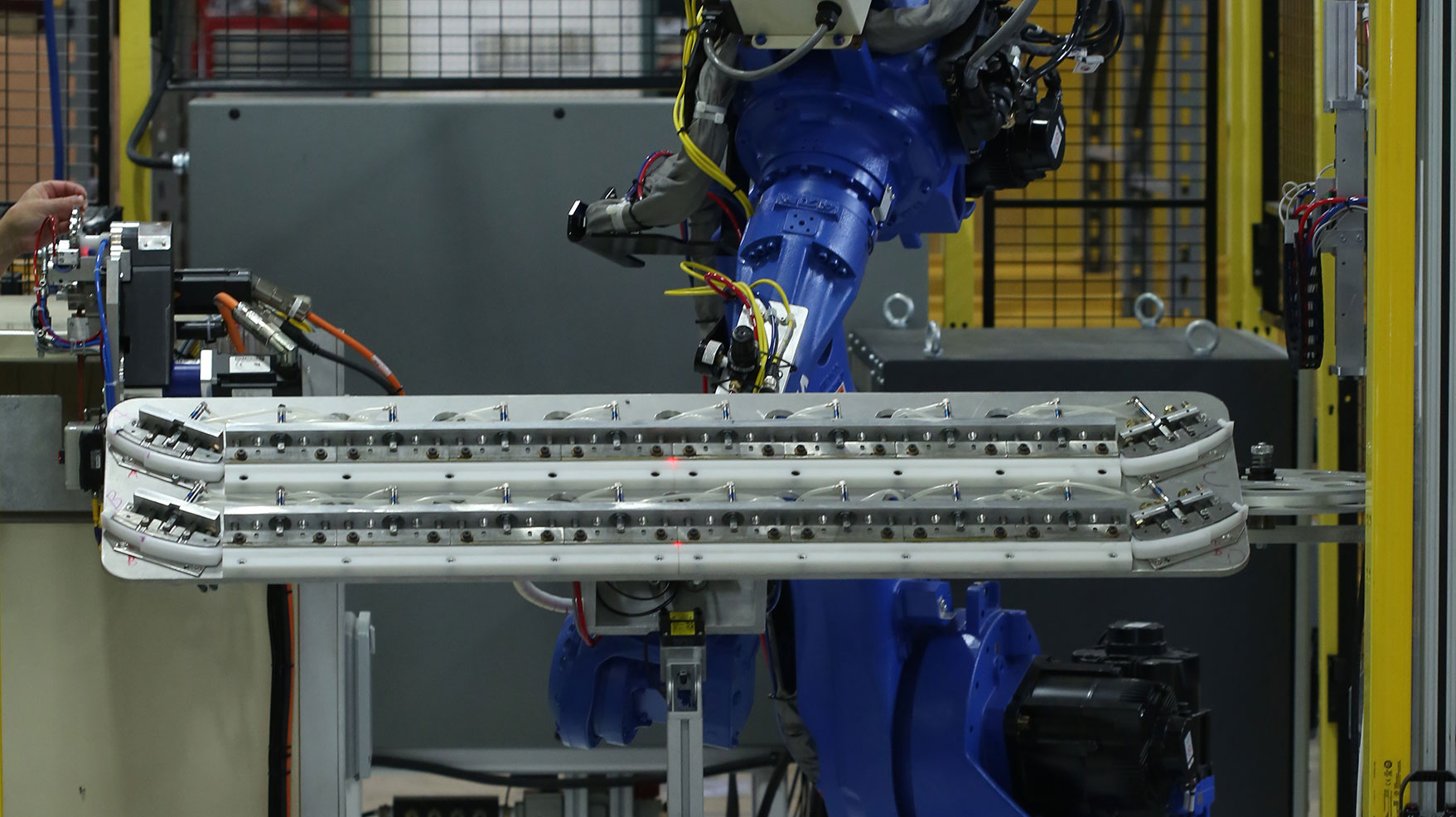

We introduced robotic cutting technology at Spring Lake to address this challenge. By strategically configuring two robotic cutting cells equipped with a high-speed router and ultrasonic knife, we achieved precise cutting of intricate shapes, including multi-axis geometrics. The cutting software can be programmed for any application, making the process easily repeatable without the need for cutting dies. This advanced technology not only solved the problem for our customers but also resulted in cost savings.

The implementation of robotic cutting opens up new possibilities for product designers and allows for more creative part designs. With our confidence in producing complex and highly angled baffles using this technology, we aim to explore further opportunities to assist our customers in realizing their visions. Whatever your needs may be, our sales team at Cooper Standard ISG is ready to help you bring your vision to life.