HVAC Sealing Solutions

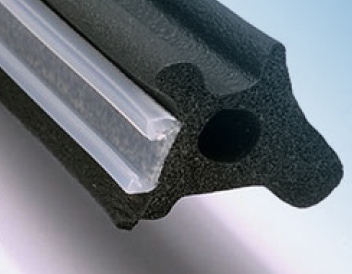

Optimizing material compounds to meet and exceed customer performance

Developing world-class designs for customers' unique applications

A leading authority in testing / advanced analytics

World-class operations / advantaged global footprint

Cooper Standard Industrial & Specialty Group (ISG) offers a unique combination of expertise in engineering, materials science, production and industry compliance. We help our HVAC industry partners design, develop and optimize any seal or gasket component for optimum performance in their equipment.

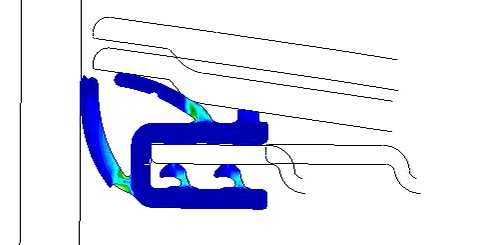

We also provide expertise in engineering capabilities, including computerized finite element analysis designed to help create the optimum sealing solution to help meet any HVAC demands.

We also offer complete customized designs from the ground up for maximum results. In fact, the earlier in the design process you tap into ISG's proven expertise the better—ISG can be a highly successful development partner for any high volume HVAC equipment manufacturer.

HVAC Sealing Design Guide

Review HVAC sealing design concepts for your next HVAC project.

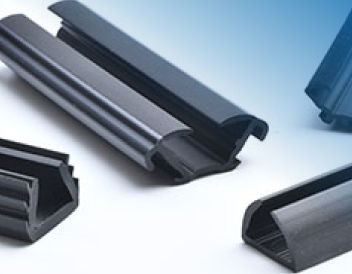

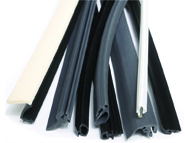

HVAC Sealing Product Solutions

Download Cooper Standard ISG's HVAC sealing capabilities.

FEA is a powerful software tool that Cooper Standard ISG experts use to help optimize seal designs. Design projects with partners across a number of industries suggest that FEA could reduce optimum development cycles and testing, significantly slashing development time and costs, and allowing faster speed to market with potentially more effective, more robustly performing products.

FEA is also the driver for a Cooper Standard innovation that is revolutionizing seal installation in many facilities. Crimp on Flange (OOF) technology often doubles the pull-off force of current seals, as well as delivers revolutionary improvements in the speed and ergonomics of assembly, reducing vibration and percussive force experienced by the operator.

- Air Duct Seals

- Boots Bellows

- Damper Blade Seals

- Airfoil Blade Seals

- Condensation Drain Tubing

- Strut Covers

- Shock Mounts

- Laminated Gaskets

- Access Door Gaskets

- Residential Furnace Seals

- Compressor Motor Mounts

- And Much More