Innovative Sealing and Fluid Handling Solutions for Truck and Bus Applications

A proven partner serving the world’s leading truck and bus manufacturers for more than 50 years, Cooper Standard ISG is your one-stop shop for high-performing engineered sealing solutions, as well as advanced fluid handling systems that can help optimize new vehicle designs and stay far ahead of the market trends, especially as trucks and buses evolve to run on hydrogen, electric and other alternative fuels.

A proven partner serving the world’s leading truck and bus manufacturers for more than 50 years, Cooper Standard ISG is your one-stop shop for high-performing engineered sealing solutions, as well as advanced fluid handling systems that can help optimize new vehicle designs and stay far ahead of the market trends, especially as trucks and buses evolve to run on hydrogen, electric and other alternative fuels.

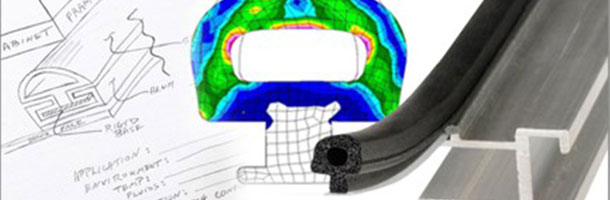

Design and Development Expertise

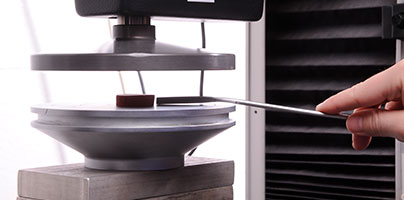

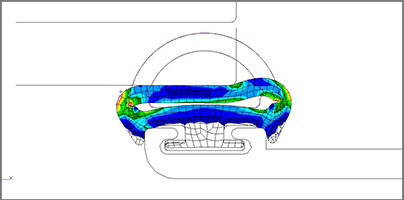

In addition to industry-leading standard engineered solutions, Cooper Standard helps truck and bus manufacturers design and develop custom engineered sealing and fluid handling solutions from the ground up. Cooper Standard delivers world-class engineering expertise, supported by computerized tools such as Finite Element Analysis (FEA), that can predict seal performance in a virtual environment, and Computational Fluid Dynamics (CFD) to precisely fine-tune fluid handling systems flow before production. These capabilities help slash development costs and accelerate time to market.

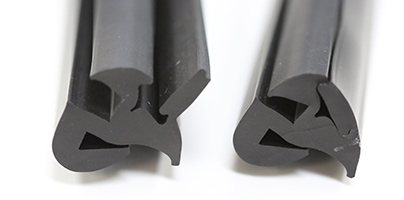

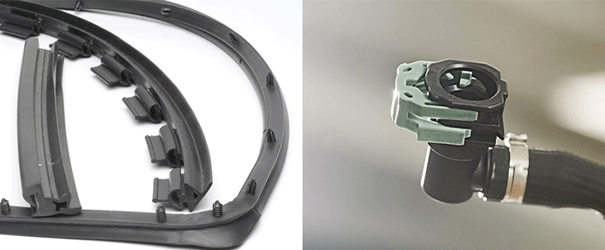

Sealing Solutions that Meet Demanding Needs

Contemporary sealing technology emphasizes comfort, safety and performance for truck and bus applications. For example, Cooper Standard seals deliver tight tolerances throughout the cab, minimizing wind and road noise, eliminating water ingress and maintaining desirable temperatures and humidity, helping keep drivers reliably on the road for the long haul.

Further, high-quality seals help optimize aerodynamics and operations even as traditional truck and bus configurations change, with designs that help account for the new sealing demands of revised door and mirror placements, onboard cameras, and evolving fueling systems.