FEA Technology improves gasket design

The use of the latest in finite element analysis (FEA) software allows Cooper Standard to optimize seal and gasket designs quickly, resulting in shorter product development cycles. Learn more about how Cooper Standard utilizes FEA technology to effectively reduce development cycles and testing, and save you time and money.

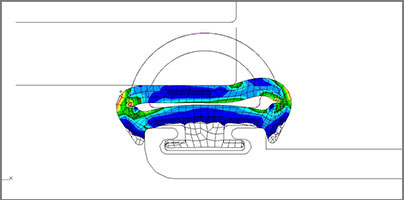

FEA technology simulates various forces on a gasket to better illustrate the stress dynamics a part will undergo.

Some of those stressors include:

- External Pressure

- Internal Pressure

- Performance under heat or cold conditions

- Deformities under pressure

Case Study

When a customer requested a more robust seal for long-term use and easier installation on commercial laundry machines, our engineers used FEA software to begin and review trials.

The FEA showed current compression points for proof of failure when compressed.

Engineers made several design changes that provide three key benefits:

- Easier installation through use of HATS adhesive.

- Controlled prototyping costs

- Improved compression points for greater seal performance.

In addition, our material experts recommended a switch in material that offered robust properties with a softer density. This significantly reduced the pressure needed for a consumer to shut the appliance door.