Foodservice Equipment Sealing Solutions

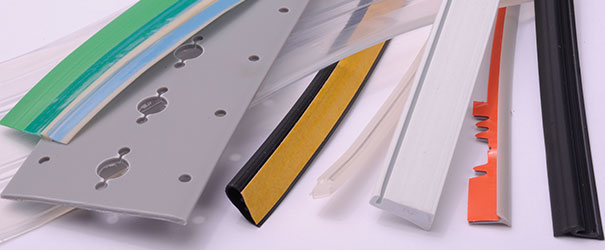

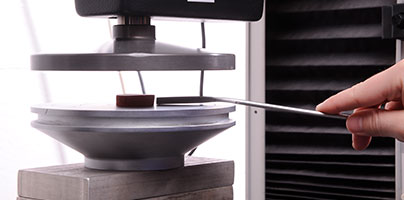

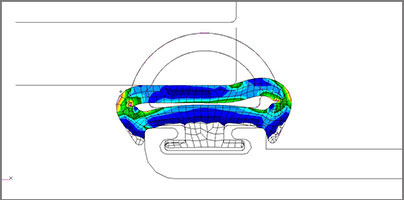

Cooper Standard Industrial & Specialty Group (ISG) delivers expert materials knowledge— including silicones, EPDMs, thermoplastics and more, as well as engineering capabilities—including computerized finite element analysis—to help our customers design a sealing solution for optimum performance in any food service equipment application.

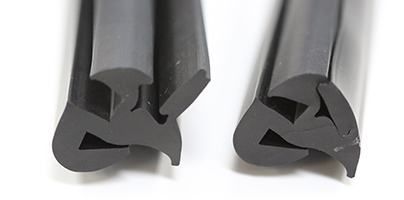

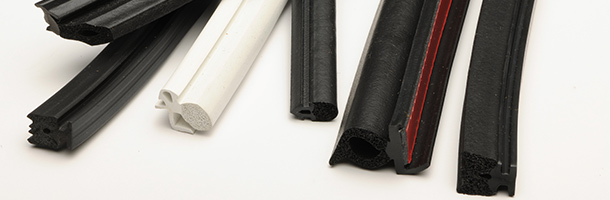

Our seals help manufacturers ensure that their food service equipment stands up effectively to key challenges such as keeping temperatures constant for energy efficiency and product integrity, maintaining mechanical properties such as compression set for long-term operating cycles, protecting delicate components against vibration, and much more, as the individual application demands.

Further, we have a portfolio of proven high-performance materials that deliver outstanding mechanical and temperature capabilities while meeting the wide ranging and stringent demands of the FDA, NSF, UL and other regulatory bodies.

We work closely with equipment manufacturers to optimize seal and gasket design for outstanding performance on new or existing equipment. Our team partners with manufacturers throughout the entire development and manufacturing cycle. From material selection (to address cost and market availability) through specialized processes (such as pre-cutting, packaging, and adding peel-off adhesive for easier handling and assembly), our experts stand ready to assist customers with their unique needs.