Plastic Materials

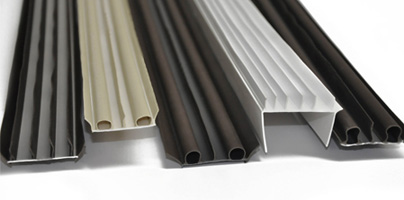

Our plastic materials can be developed to meet many custom or standard needs. These include operating temperatures, UV resistance, coloration or opacity, flame resistance, rigidity and more.

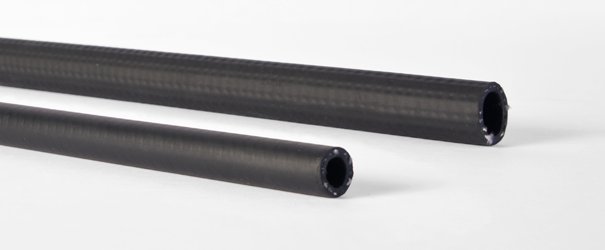

Depending on your application's unique demands, plastic compounds can produce extremely rigid profiles or mimic the physical properties of rubber. Some common applications we support include heavy truck air baffles, TPV glass run channels, residential and commercial window and door seals and more. Whether you need a simple profile, a multi-durometer extrusion, or a specific color, our wide range of materials allows us to optimize solutions for your price and performance requirements.

From selecting materials to part design, Cooper Standard engineers work directly with you to solve problems.