Sealing Systems

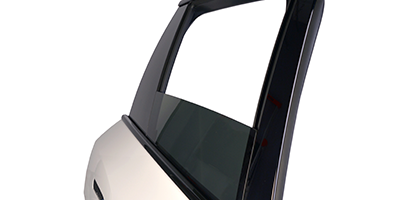

We are the leading provider in global sealing systems with award-winning products and recognition as a trusted partner. Our target is to be more than the largest provider, but the sealing benchmark, to be the First Choice of the Stakeholders We Serve. As the industry evolves, we expect to see an increase of electric vehicles with a focus on appearance, lightweighting, noise reduction and sustainability. We offer a variety of innovative solutions to address our customers’ current and future needs. Learn more.

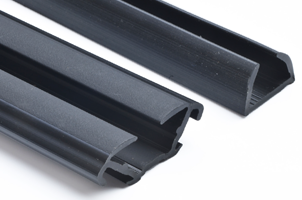

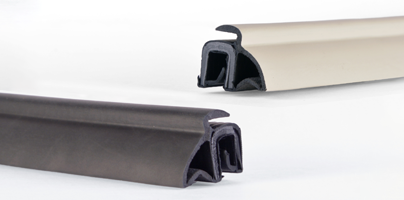

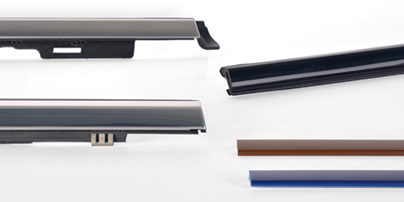

Our blend of elastomers and thermoplastics makes our sealing products recognizable across all industries, including automotive, pharmaceutical, appliance, HVAC, lighting, commercial and residential window and door, truck and bus, power sports, electrical vehicle, food services, and many others. From choosing the right material to applying cost-effective manufacturing methods, we provide superior solutions for our customers across diverse powertrains and markets.

- Fortrex®, Rubber, Silicone & Plastic Materials

- Custom Designs

- Standard Profiles & Catalog Parts

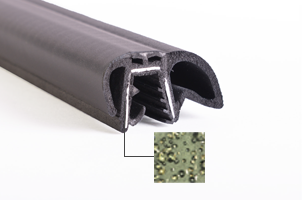

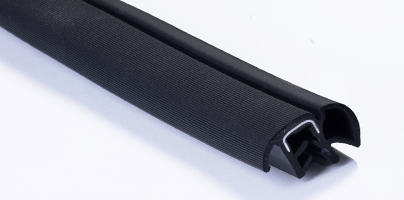

- Clip-On Seals

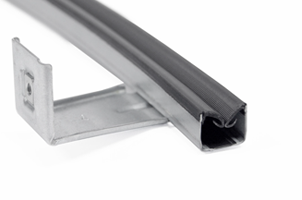

- Metal, Plastic or Wire Carriers

- Extrusion: EPDM, Silicone, Neoprene, Nitrile, Thermoplastics

- Custom Industrial Extrusions

- Automotive Sealing System Extrusions

- Finishing Capabilities

- Graining

- Hole Drilling and Pin Insertion

- Coating Application

- Bending

- Notching

- Die-Cut

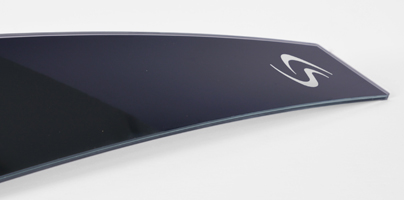

- Glass Encapsulation

- And More