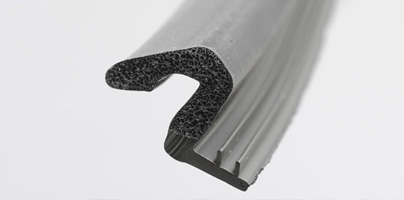

Custom Rubber Extrusions

VERSATILE CAPABILITIES

Our rubber extrusion operations are built on the belief that every customer's need is unique. Cooper Standard custom extrudes rubber for various industries from a wide variety of compounds, grades and specifications.

We can help you through the entire extrusion process – from choosing the right material to using the most cost-effective manufacturing methods.

OUR SERVICES

Rubber sealing components protect, dampen vibration or aesthetically enhance finished products for appliance, HVAC, automotive, lighting, commercial & residential window and door, power sports, food services, electrical vehicles and many others.

There are many decisions to consider when designing a seal or gasket. When you partner with Cooper Standard, we offer the following services to develop or refine a seal that meets your custom needs.

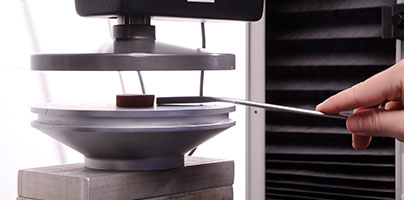

- Material Formulation and Testing

- Engineering Design

- 2D and 3D Finite Element Analysis (F.E.A.)

- 3D Modeling

- Equipment Development

- In-house Tool Capabilities

RUBBER MATERIAL OFFERINGS

Cooper Standard gives you access to advanced materials science and expertise. We can develop materials to meet industry standards. Partner with our engineers to discover what rubber material is right for you according to your unique specifications.