Fluid Transfer Systems

Cooper Standard's products Convey, Connect, Control and Communicate (our 4C product development strategy) throughout fluid systems for optimal powertrain operation and passenger comfort. Our portfolio of fluid transfer products address the full spectrum of powertrain and temperature requirements including electrified vehicles. These next generation products also offer game-changing weight reduction, abrasion resistance, corrosion protection and finished assembly aesthetics.

In addition, our fuel and brake delivery systems efficiently support the transfer of critical fluids in various types of recreational, specialty and industrial vehicles. By integrating plastic molded components, we create more efficient assemblies for coolant tube, heater hose, water hose and radiators and installation processes can be improved through our quick connect and joint solutions.

Fluid Transfer Capabilities

- Hose Extrusion

- Hose Forming and Finishing

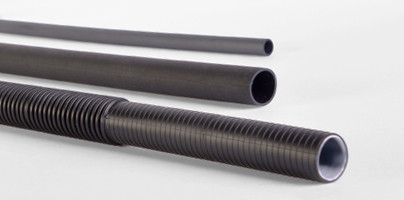

- Monowall and Multilayer TP Tubing Extrusion

- TP Tube Forming and Finishing

- Injection Molding

- Quick Connector Assembly

- Metal Tube Milling (Welded and Brazed)

- Tube Base Coating (Hot Dip Alloy and Plating)

- Tube Coating (PA, PP)

- Tube Endforming & Bending

New electrified vehicles must maintain low component and fluid mass to meet vehicle driving range goals while providing necessary thermal management functions. This shift has brought about the development of materials and structures which can now be utilized to convey coolant from one place to another and provide serviceable and robust connections. Cooper Standard’s lightweight thermoplastic system solutions (PlastiCool® 2000 MLT, Ergo-Lock™+ and Easy-Lock® Quick Connectors) are exceeding expectations to address the new conditions encountered in these electrified systems. Learn more.