Choosing Material

Choosing Material

Selecting the best elastomer for an application requires a thorough understanding of the application and performance requirements.

Choosing the right material can be a daunting task. However, the first step is to pre-determine the conditions to which the end product will be exposed. Some of these include:

- Temperature and other environmental factors

- Physical, mechanical and chemical resistance requirements

- Industry standards requirements such as UL, ASTM, SAE, FDA, NSF and U.S. Military Standards

Improve Your Next Design

Learn more about selecting the right materials and processes with our Sealing Design Guide.

Download NowThe right compound

The initial compound is essential to the entire design process. A small change to the accelerators or age resistors, and the finished compound meets or misses standard industry requirements.

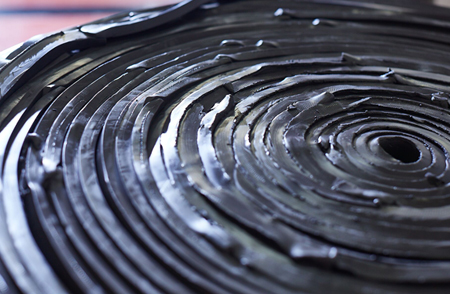

Most rubber polymers have limited commercial value in their original state. Therefore, a compound “recipe” must be developed to enhance or add to a polymer’s inherent physical and chemical characteristics and to ensure efficient molding or extruding. In creating the proper recipe, a compounder needs to be aware of a number of chemical or technological factors:

- The customer’s technical specifications

- Individual polymer properties

- Additives that can alter price, processing and vulcanizing/curing systems

- Anti-degradants

- Mixing procedures

- Testing/quality assurance methods

.