Window and Door

Protecting enclosures against leakage with comprehensive design solutions

Engineering standard and custom solutions, versatile to every need

Specifying the right material for the job from a broad material portfolio

Reducing tooling costs and time to market with digital simulation tools

Cooper Standard ISG offers engineering expertise to help design unique, mission-specific seals that impart key performance criteria such as desired compression load deflection, leak resistance, operational force requirements, opening/closing cycles, reduced assembly time and other properties to the finished product.

We provide outstanding experience with rubber, and thermoplastic extrusion and molding, including hybrid parts, and we are pioneers in performing finite element analysis that can identify potential seal failure modes.

Cooper Standard ISG can also help you plan optimum assembly and a seal insertion method with value-added production capabilities and a wide range of potential insertion options.

Sealing Solutions and Product Offerings

Download a list of standard window and door products or learn more about our custom sealing solutions including engineering support, materials expertise and vast product offerings.

Door Seals & Sweeps

Improve installation and performance with our EPDM door seal and TPE door sweep. Download and explore our standard profiles and benefits of using a Cooper Standard ISG seal.

Improve Your Next Design

Download our Sealing Design Guide for an in-depth resource to help you optimize part production and performance.

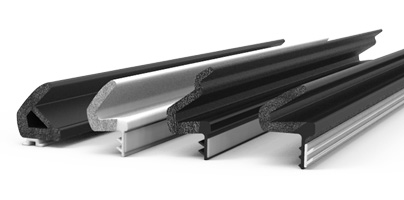

Cooper Standard ISG also offers high quality standard residential and commercial profiles proven in use by window and door manufacturers worldwide, including:

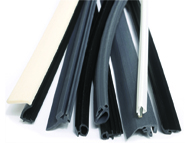

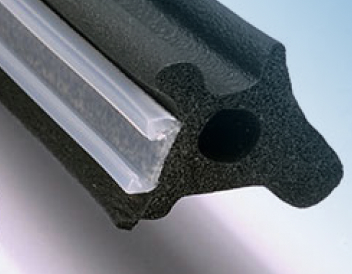

- EPDM Entry Door Seals

- TPE Door Bottoms and Sweeps

- Curtain Wall Gaskets & Seals

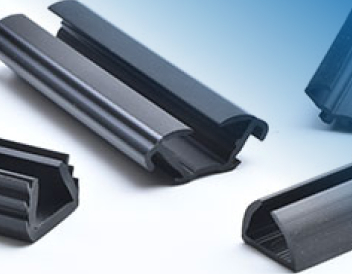

- EPDM Kerf-Mounted Seals

- Silicone Fire-Rated Door Seals

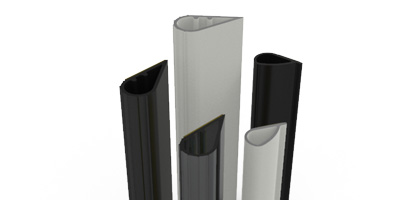

- Slide-In/Push-In Seals

- Glazing Gaskets

- Universal Profiles

- Setting Blocks

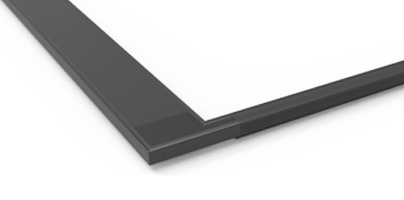

- Continuous Corner Seals

Many standard components are certified by FGIA and on their AAMA 702-11 Class A Verified Components List, with more being added all the time. These currently include:

- Kerf Mounted Weatherseal

- iDea® Seal Sponge Weatherseal

- iDea® Seal Dense Weatherseal

- Entry Door Weatherseal