Indow Inc. and Cooper Standard ISG Partnership

Working Together to Bring Energy Efficiency to Vintage Windows

Sam Pardue - now Indow founder and CEO loved living in his classic 1906 Portland Craftsman house with its historical structure and original architecture features, however, its single pane glass windows were leaky, boosting his gas bill and wasting a significant amount of energy.

Sam Pardue - now Indow founder and CEO loved living in his classic 1906 Portland Craftsman house with its historical structure and original architecture features, however, its single pane glass windows were leaky, boosting his gas bill and wasting a significant amount of energy.

“There seemed to be no solution other than to replace the original windows with modern, high efficiency ones,” he said. “But I couldn’t bear to rip out these gorgeous windows with their old growth timber, handcrafted wood frames and beautiful rippling glass,” he said.

Pardue's original solution included adding an acrylic panel between the window and the room to seal out drafts without impacting the original architecture. After multiple failed experiments with various systems to maintain air tightness around the edges without having to damage the window cavity, Pardue realized the true complexity of what needed to be done.

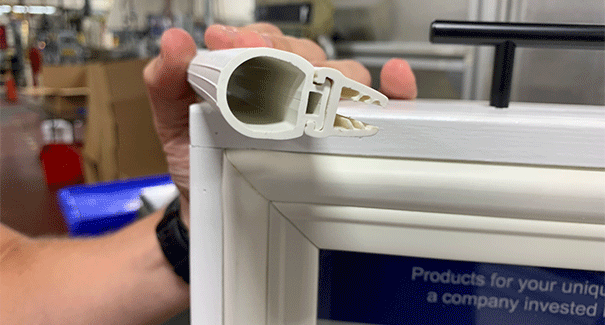

"Window are a very harsh environment and undergo a wide range of temperatures through the day and year. With the sun beating down on a summer afternoon or a freezing win blowing on a cold winter night, the cavity can get up to 130°F or more, or down to 40°F or less, which causes the acrylic to expand and contact," he explained. "We needed compression tubing that not only consistently stayed tight, but did so even as the edges of the window thermally expanded and contracted."

Pardue realized in order to find an optimal solution, choosing the right material was crucial. After researching multiple materials, Pardue concluded that silicone was the best material because of its outstanding compression set and temperature resiliency.

Because of their need for high-quality silicone products, Pardue was led to their soon to be long-term business partner, Cooper Standard ISG.

Silicone Expertise with Long-Term Outlook

"With research, we found that there are quite a few silicone extruders out there, but Cooper Standard ISG rose quickly to the top of our list," noted Pardue. It's rare to find expert engineers who specialize in designing silicone seals from scratch."

He also found that Cooper Standard ISG was one of the few companies who formulated their own silicone as opposed to buying it from third parties.

"Their vertical integration and deep knowledge of the material properties allowed them to create a custom silicone recipe for us that optimizes both performance and aesthetics," Pardue explained. "They were not only able to build in compression strength and other performance properties we needed, but they also assisted with assembly and operation, and served as a host of aesthetic properties."

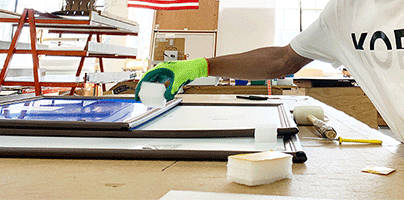

Cooper Standard ISG helped create the acclaimed Indow inserts, a big hit among thousands of homeowners around the country because of their air-tight, highly efficient solutions, with no changes to their current window systems of architecture. The Indow inserts also gained enough popularity to be featured in several episodes of the television show, "This Old House."

"The inserts leave your existing windows almost completely untouched, thanks to the patented compression seals that press into place and stay tight for the long term, said Pardue. "The inserts are basically invisible once they are installed, and yet, the U.S. Department of Energy found they can lead to a 20% reduction in heating and cooling costs."

A Partner That Continually Adds Value

Pardue notes that the initial selection of Cooper Standard ISG as a supplier has led to a 12-year partnership that is continuously growing, along with a constant stream of value-added efforts to benefit both companies.

"Cooper Standard ISG helped us develop the initial silicone material and extrusion dye that we used to start the company and we've been working with them ever since," he said. "In fact, in 12 years we've never had a durability related warranty issue relating to the silicone compression bulb - that speaks to the high quality formulations and manufacturing."

Cooper Standard ISG has also made efforts to continually add value to the partnership.

These efforts have included continued new product development, such as the creation of seals for Indow kits, a line extension which allows homeowners to benefit from a new type of seal that expertly combines silicone with ABS plastic for ease of installation.

"Innovation can best happen when you have a partner that helps you bring your idea to fruition," said Pardue. "There is no doubt in my mind that Cooper Standard ISG has been an indispensable part of the Indow growth and success story. Without their expertise, we would not be where we are today."