Construction Equipment Sealing and Fluid Handling Solutions

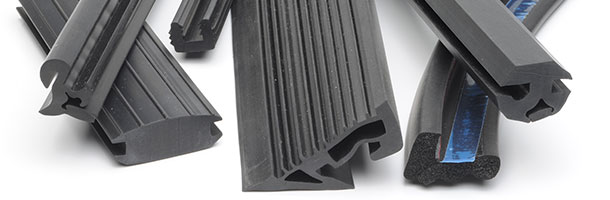

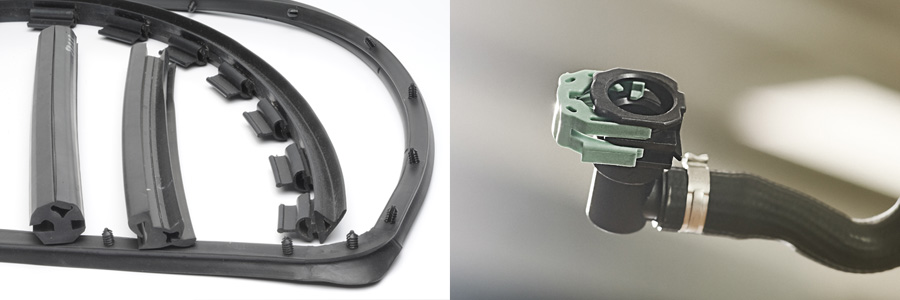

Cooper Standard Industrial & Specialty Group (ISG) designs and manufactures custom or catalog seals and fluid handling solutions that are proven to stand up to the punishment of construction site conditions. Whether on a truck, loader, leveler, plow, or crane, our cab seals are custom designed to keep the interior environment free of dirt, dust, water and grime, while helping keep it quiet and comfortable for passengers.

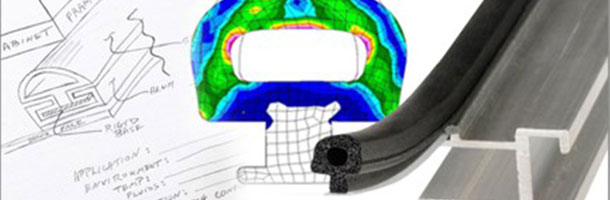

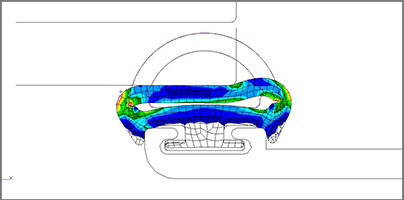

Cooper Standard ISG also utilizes Finite Element Analysis Technology (FEA) and Computational Fluid Dynamics (CFD) to help optimize our sealing and fluid-handling systems for superior product performance.

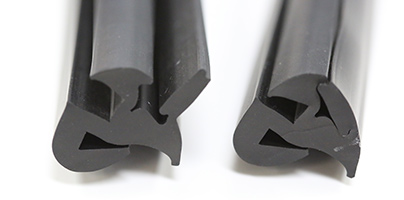

Further, Cooper Standard's innovative Crimp on Flange (COF) technology doubles the pull-off force of glass cab door seals and reduces assembly time over incumbent methods. As a result, seals remain in place through thousands of cycles, rough handling and rugged environments.