Open-Cell Vs Closed-Cell Rubber

Open-Cell Vs Closed-Cell Rubber

A key benefit of closed-cell sponge rubber is its ability to resist water absorption. Here's a closer look at how it works:

Sponge rubber is extruded by including a gas-forming ingredient (blowing agent) in the rubber formulation.

As the rubber passes through heating zones in the cure system, it reaches a temperature at which the blowing agent decomposes and gas bubbles form, creating individual cell structures in the rubber.

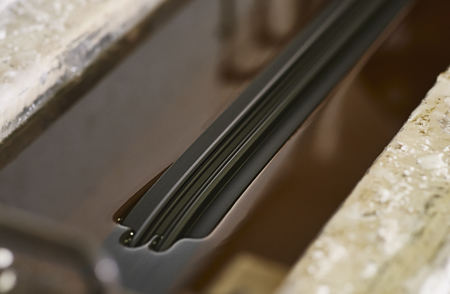

On this extrusion line, the rubber is cured as it passes through a high-temperature salt bath.

Material Qualities

Cooper Standard ISG specializes in closed-cell sponge rubber products. This material consists of enclosed cells independent from other cells, each with its own structure.

Closed-cell rubber doesn't let fluids seep in and stays afloat in water.

Open-cell rubber has distinctive cells that are open and interconnected to neighboring cells. This lets air and moisture seep in easily, giving the rubber an absorbent quality.

Both open-cell and closed-cell products offer superior compression qualities when compared to a dense material. Learn more about rubber compression properties.

A closed-cell rubber extrusion.