Rubber Properties

Rubber Properties

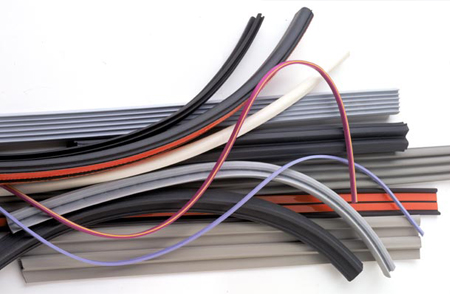

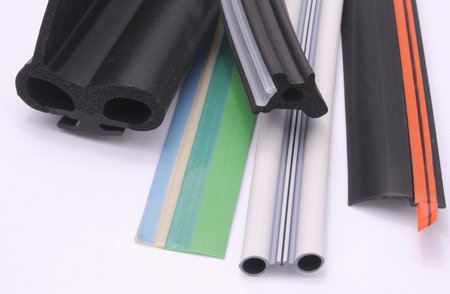

Cooper Standard ISG gives you access to many advanced rubber compounds. Our material expertise and integrated production capabilities allow us to provide:

- Control over all aspects of the material development process

- Faster turnaround times

- High customization

- Increased responsiveness

- Superior quality

We can develop materials to meet most major industry standards including: AAMA, ASTM, DIN, FDA, JIS, NSF, MIL, Reach, RoHS, SAE, UL & more.

Improve Your Next Design

Learn more about selecting the right materials and processes with our Sealing Design Guide.

Download NowEPDM (Ethylene Propylene Diene Monomer)

EPDM seals and gaskets are well known for ozone, weathering and aging resistance.

EPDM rubber also has excellent water and steam resistance, maintains its flexibility at low temperatures, features excellent resistance to alkalis, acids and oxygenated solvents, and is very color stable.

It is not recommended for resistance to oil, gasoline and hydrocarbon solvents. EPDM rubber seals and gaskets are found in a wide range of applications and are excellent for use outdoors.

These sealing solutions can be found in applications ranging from basic commodities such as hoses, belts and o-rings to complex, highly engineered seals for automotive, window, door, mass transit and more.

Cooper Standard ISG offers custom closed-cell sponge and dense EPDM rubber extrusions.

VMQ (Silicone)

Silicone rubber compounds are the preferred choice if you have an application that requires high heat or very low temperatures.

Sponge silicone and dense silicone compounds may be selected based on the needs of your application. Silicone offers enhanced color stability, allowing full color-matching capabilities.

Benefits of silicone

- Resistance to ozone

- Resistance to sunlight and oxidation

- Excellent flexibility at low temperatures

- Excellent resistance to extreme temperature fluctuations

- Excellent electrical insulation

- Superior color stability

- Low compression set

CR (Chloroprene/Neoprene)

A good blend of properties including resistance to abrasion, flex cracking and oils.

Neoprene seals and gaskets offer moderate resistance to oils and gasoline. Neoprene features good flame resistance, weathers well, and has very good resistance to abrasion, flex cracking, alkalis and acids. However, expect poor resistance to aromatic and oxygenated solvents and limited flexibility at low temperatures.

Neoprene seals and gaskets are generally considered an excellent all-purpose solution with a solid balance of properties and few limitations.

NBR (Nitrile)

Nitrile seals and gaskets have very good oil and gasoline resistance, permeability and heat and abrasion resistance.

Nitrile’s resistance to alkalis and acids all increase as the nitrile content of the compound increases. Nitrile seals and gaskets must be specially compounded for resistance to ozone, sunlight and natural aging, and they have poor resistance to oxygenated solvents.

Nitrile is superior to neoprene in oils and solvent resistance but is not recommended for applications where it is exposed to severe weathering.

PUR (Polyurethane)

This polymer exhibits very good mechanical properties and has good resistance to weathering, as well as gas or oil.

Polyurethane seals and gaskets also demonstrate excellent adhesion to fabrics or metals.

It comes in several forms (dry or liquid) as well as base chemistries which govern the level of performance of the properties listed above.

FVMQ (Fluorosilicone)

Fluorosilicone rubber is used in demanding applications where the extreme service temperatures are required along with resistance to fuels, coolants and oils. The fuel resistance sets Fluorosilicone apart from silicone rubber seals and gaskets.

Fluorosilicones exhibit excellent weathering characteristics and compression set resistance. For demanding environments where abrasion and tear resistance are not critical, Fluorosilicone seals and gaskets can provide improved performance over Fluorocarbon polymers.