The demand for dishwashers is rapidly increasing in both residential and commercial markets, fueled by evolving consumer lifestyles, innovative kitchen designs and growth in the hospitality and healthcare sectors. Consumers are seeking advanced features such as energy and water efficiency; improved sanitation and faster cleaning cycles.

In response, proactive appliance manufacturers are innovating quickly, developing new dishwasher concepts that align with customer expectations. These innovators are effectively gaining market share, increasing profits, and enhancing brand reputation across multiple market segments.

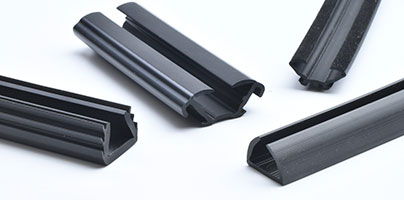

Cooper Standard Industrial & Specialty Group helps dishwasher manufacturers by providing high-quality door seals that are crucial for the success of new and existing dishwasher designs. Our world-class sealing solutions eliminate leaks and condensation, streamline assembly processes, reduce tolerance variations, minimize warranty claims, enhance the feel of opening and closing, and maintain door integrity over thousands of cycles.

We specialize in developing optimal seals for dishwashers and other appliances, ensuring excellent performance in the long term. Our engineering team can seamlessly integrate with your design team to create custom seals or refine existing designs for better manufacturability and performance. Contact us today to start your next project!

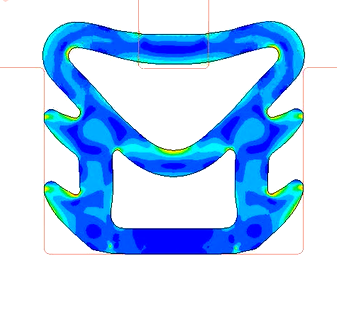

Digital Simulation and Virtual Validation

We provide cutting edge support tools including in-house industry testing and validation equipment, along with expert use of computerized finite element analysis (FEA) and Computational Fluid Dynamics (CFD) modeling. These tools simulate the performance attributes of seals, tubes and hoses over time, optimizing performance and reducing the need for extensive prototypes.

Accelerate Time-To-Market with In-House Testing

Cooper Standard maintains a host of highly specialized testing and validation equipment, speeding up the custom seal design and development process. Our testing capabilities include:

- Thermal Analysis

- Fourier Transform Infrared (FTIR) Spectroscopy

- Compression Load Deflection

- Adhesion Force Tests

- Sliding Resistance Tests

- Reverse Engineering

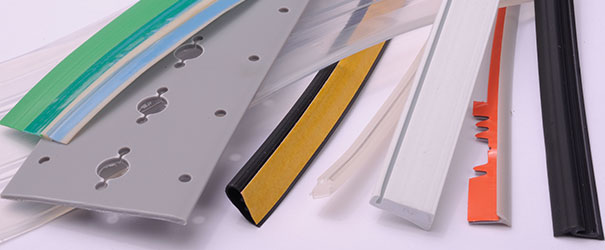

Whether designing and developing a new product, working to improve the sealing capabilities in an existing one, or helping you identify a high performing alternative to an incumbent material, Cooper Standard ISG engineers can provide unmatched materials knowledge and compounding expertise. No matter what the challenge, our engineers can help custom develop a component to meet it. The high performance rubber and thermoplastic materials in our portfolio include:

EPDM

EPDM offers excellent compression performance with a favorable cost profile. Cooper Standard ISG formulates the material to meet FDA/NSF requirements, with available products in sponge and dense materials and colorized options. See more about our EPDM materials and how we can help optimize your applications with high-quality rubber.

Silicone

Cooper Standard ISG is highly experienced at specifying and compounding silicone for extreme temperature applications, including low and high-temperature storage equipment. We offer dense and sponge silicone formulations, provide color options, and meet FDA/NSF compliance regulations. Learn more about our silicone's working temperature or custom silicone extrusions.

PVC

Our proven PVC processing expertise involves spanning grades from rubbery soft, to semi-rigid, to rigid. This process can help food service equipment manufacturers achieve outstanding sealing solutions at even the most sensitive budget levels.

Fortrex™

A proprietary Cooper Standard innovation, Fortrex™ is a lightweight elastomer with a unique property set, demonstrating excellent compression, high weatherability and aesthetic performance—and it’s environmentally-friendly as well.

Thermoplastics

Cooper Standard ISG engineers can help you develop a superior cost/performance value story with our in-house thermoplastic material expertise, including polypropylene, polyethylene, nylon, Santoprene, and Fortrex™.

We can be a highly effective partner for you. Here are just a few of the valuable capabilities that we can bring to the table:

- Colorable materials such as EDPM and silicone to indicate correct installation

- Food-grade and anti-microbial seals that inhibit the growth of bacteria, mold and mildew

- Bulk spooled sealing that helps prevent leaks and improve water efficiency

- Precision cut lengths to provide a stable, watertight seal

- One-piece, continuous welded perimeter door seals with 90° spliced angles to prevent deformation and ensure a consistent seal.

- A US-based supplier, helping you bring manufacturing back from overseas

- Identify comparable or superior performing material alternatives

- Provide a fast, reliable and cost-effective source of supply

- Purchase and reverse engineering equipment from all over the world

- Troubleshoot issues such as spotting, condensation and leaks, and implement effective solutions through material and design modifications.

- Test, evaluate and benchmark existing sealing and fluid handling solutions and develop superior alternatives for our partners.

Cooper Standard ISG has the resources and skills that can help appliance manufacturers develop the optimum custom engineered sealing solution for any new or upgraded dishwasher or other appliance design fast. Contact us today to get started.

Improve your new or existing seal or gasket design by selecting the proper polymer materials and processes.