Appliance Sealing Solutions

Cooper Standard Industrial & Specialty Group (ISG) can work with you to design—or redesign—a sealing solution for optimum performance in any appliance application.

Cooper Standard ISG’s unique mix of world-class product development, engineering and materials expertise—as well as in-house testing and validation capabilities—can help appliance OEMs build in robust sealing performance in any new product. We also provide expertise in engineering capabilities, including computerized finite element analysis designed to help create the optimum sealing solution to help meet the demands of any appliance application. Cooper Standard ISG can also work with you to create a new seal to decisively solve performance or warranty issues that may be plaguing an existing product.

In addition, Cooper Standard ISG can help you specify high-performing materials to replace an incumbent material which may be impacted by emerging regulatory issues. Our engineering teams can integrate seamlessly with your in-house staff for synergistic and highly effective partnerships—whether project-focused or for greater success long term.

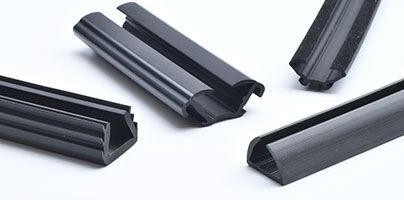

Optimizing appliance components

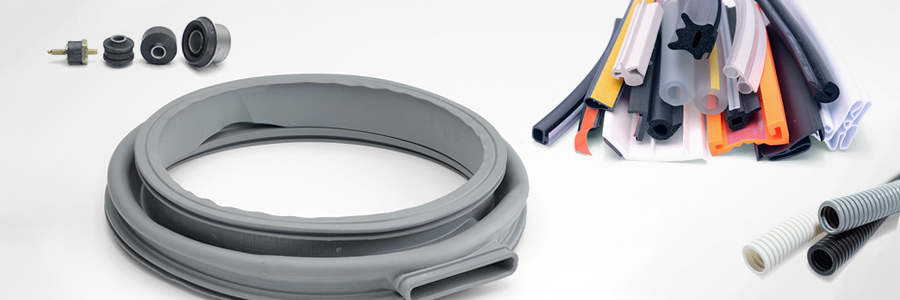

With experience on projects for some of the world’s largest and most demanding appliance manufacturers, look to Cooper Standard ISG for high performance sealing solutions for many key industry applications including:

- Appliance Door Seals

- Seals & Gaskets

- Anti-microbial Seals

- Temperature Resistant Seals

- Seal Boots

- Grommets

- Bellows

- Isolators

- Connectors

- Plugs

- Welded Corners

- Convoluted Drain Tubes