Driven by consumer demand, today’s washer and dryer manufacturers are experiencing a surge of creativity and innovation, launching feature-rich units with cutting edge technologies focused on energy efficiency, smart wi-fi connectivity, sanitizing capabilities, quiet operation, anti-microbial and antifungal properties, removable agitators and compact all-in-one designs for small spaces.

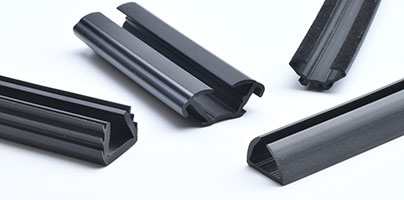

Cooper Standard Industrial & Specialty Group is partnering with leading washer and dryer manufacturers to capitalize on these opportunities. With each new design, door seals need to be reimagined. Although they are a small component of the final product, our high quality, industry-leading door and tub seals play a crucial role in the success of both new and existing laundry equipment. They help prevent leaks and condensation, retain heat, streamline assembly, reduce warranty claims, optimize opening and closing, maintaining door integrity over thousands of cycles in both stainless and plastic door substrates.

Cooper Standard ISG specializes in high-performance seals for industrial applications, including laundry equipment and other appliances. Our seals are designed for optimal compression set, push on/pull off force, and key properties for long-term performance. We offer metal-to-rubber bonding for effective isolators and shock absorbers to reduce vibration and noise.

Our engineers can integrate with your team to develop custom seals or vibration damping solutions, refine designs for cost reduction and operational improvement, and make adjustments for challenging areas or precise tolerances.

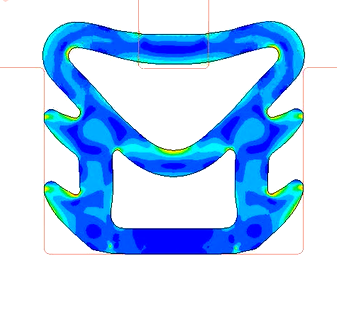

Digital Simulation and Virtual Validation

We provide cutting edge support tools including in-house industry testing and validation equipment, along with expert use of computerized finite element analysis (FEA) and Computational Fluid Dynamics (CFD) modeling. These tools simulate the performance attributes of seals, tubes and hoses over time, optimizing performance and reducing the need for extensive prototypes.

Accelerate Time-To-Market with In-House Testing

Cooper Standard maintains a host of highly specialized testing and validation equipment, speeding up the custom seal design and development process. Our testing capabilities include:

- Thermal Analysis

- Fourier Transform Infrared (FTIR) Spectroscopy

- Compression Load Deflection

- Adhesion Force Tests

- Sliding Resistance Tests

- Reverse Engineering

Whether designing and developing a new product, working to improve the sealing capabilities in an existing one, or helping you identify a high performing alternative to an incumbent material, Cooper Standard ISG engineers can provide unmatched materials knowledge and compounding expertise. No matter what the challenge, our engineers can help custom develop a component to meet it. The high performance rubber and thermoplastic materials in our portfolio include:

EPDM

EPDM offers excellent compression performance with a favorable cost profile. Cooper Standard ISG formulates the material to meet FDA/NSF requirements, with available products in sponge and dense materials and colorized options. See more about our EPDM materials and how we can help optimize your applications with high-quality rubber.

Silicone

Cooper Standard ISG is highly experienced at specifying and compounding silicone for extreme temperature applications. We offer dense and sponge silicone formulations, provide color options, and meet FDA/NSF compliance regulations. Learn more about our silicone's working temperature or custom silicone extrusions.

PVC

Our proven PVC processing expertise involves spanning grades from rubbery soft, to semi-rigid, to rigid. This process can help residential or commercial washers and dryers achieve outstanding sealing solutions at even the most sensitive budget levels.

Fortrex™

A proprietary Cooper Standard innovation, Fortrex™ is a lightweight elastomer with a unique property set, demonstrating excellent compression, high weatherability and aesthetic performance—and it’s environmentally-friendly as well.

Thermoplastics

Cooper Standard ISG engineers can help you develop a superior cost/performance value story with our in-house thermoplastic material expertise, including polypropylene, polyethylene, nylon, Santoprene, and Fortrex™.

We can be a highly effective partner for you. Here are just a few of the valuable capabilities that we can bring to the table:

- Colorable materials such as EDPM and silicone to indicate correct installation

- Bulk spooled sealing that helps prevent leaks and excess moisture

- Precision cut lengths to provide tight tolerances in metal fabrication

- One-piece, continuous welded perimeter door seals with 90° spliced angles to prevent deformation and ensure a consistent seal

- A US-based supplier, helping you bring manufacturing back from overseas

- Identify comparable or superior performing material alternatives

- Provide a fast, reliable and cost-effective source of supply

- Test, evaluate and benchmark existing sealing and fluid handling solutions and develop superior alternatives for our partners

Cooper Standard ISG has the resources and skills that can help appliance manufacturers develop the optimum custom engineered sealing solution for any new or upgraded washer, dryer or other appliance design fast. Contact us today to get started.

Improve your new or existing seal or gasket design by selecting the proper polymer materials and processes.